EcofitecOur ULTRACUT rangePlasma

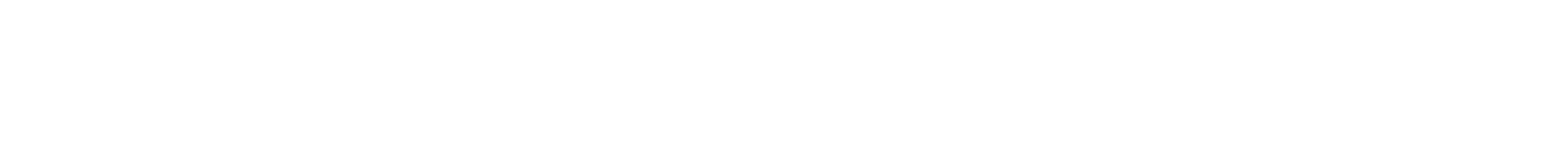

Ultra-Cut® XT technology offers the next generation of high-precision plasma cutting that's more productive, more flexible and more reliable. Ultra-Cut XT systems offer the flexibility needed to increase cutting power, ensuring superior quality and productivity, and lower cutting costs. Ultra-Cut XT systems are available in 130 to 400 A versions for cutting plates up to 50 mm thick. Their performance equals or surpasses all competition on mild steel and is superior on non-ferrous metals. With lʼUltra-Cut XT, choosing the ideal system is no longer a problem.

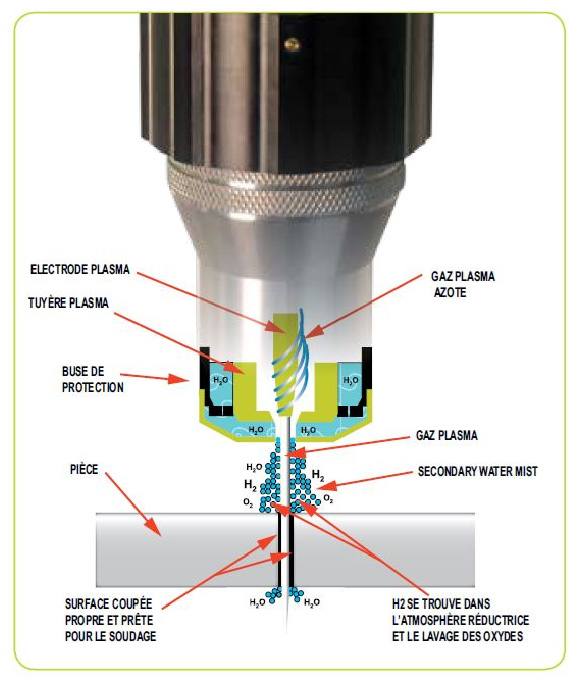

EcofitecThe Water Mist Secondary (WMS) processWMS

Optimizes cutting of non-ferrous metals

WMS benefits

For all requests for please contact us: